History of the company

The history of Jihostroj, the top Czech manufacturer of hydraulic systems and aerospace devices, started in 1919. The industrial company was incorporated in Velešín shortly after the declaration of the independent Czechoslovakia and today’s holding continues to follow its tradition.

Velešín, a municipality in South Bohemia, was established near a merchant route in the 13th century. This rural region, distant from the capital, remained undeveloped for a long time. People who wanted to have a better life often relocated, just like Jan Hans, who got a job in an electrical engineering plant in Vienna.

Following the declaration an independent Czechoslovakia, Jan Hans returned from Austria to his hometown of Velešín. He wished to utilize his know-how under the conditions of the new Republic. He combined his efforts with his relative, Jan Crkva, then-mayor of Velešín, and Josef Bürger, then-holder of an important office in the capital city of Prague.

The company JEVAN was established on 1 March 1919. This first predecessor of today’s Jihostroj offered telegraph and telephone apparatuses. The company took advantage of the situation when the new Republic needed to build a telecommunication network across its entire new territory.

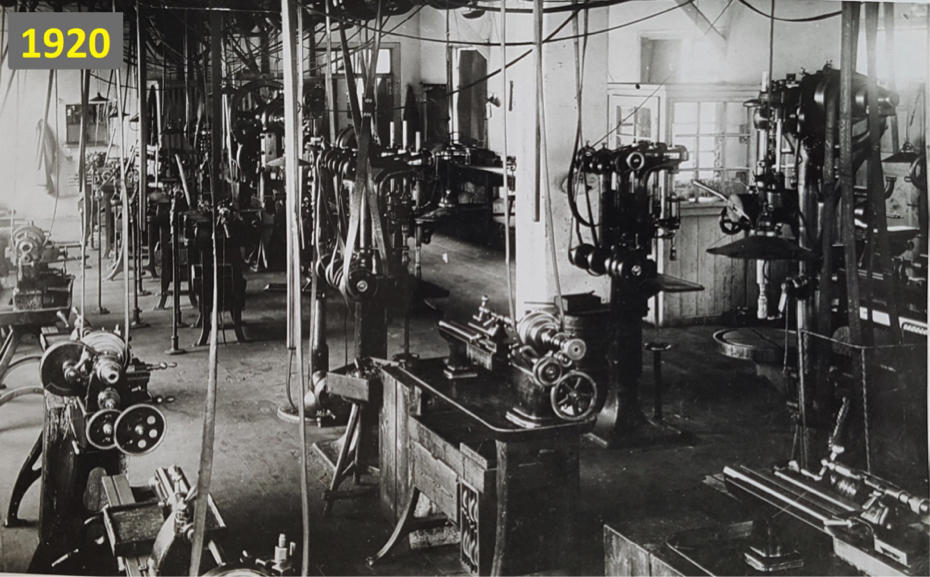

Three companies supplied similar goods on the market that time. The biggest of them was Telegrafia, with the majority share held by the state. All three manufacturers merged in 1920. The plant in Velešín became an affiliate of Telegrafia with the corporate office situated in Pardubice.

In 1925, the corporate office of Telegrafia decided to relocate all manufacturing facilities to Pardubice. Employees of the Velešín plant were offered to move, with only one-third of them deciding to do so.

Part of the remaining employees established a cooperative titled “Radio” under the leadership of Jan Hans. This title reflected the production portfolio that included parts for radio receivers. The former employees of Telegrafia were not allowed to use the original buildings; therefore the cooperative built a new facility nearby. In 1934 the Radio cooperative was dissolved due to the impact of the economic crisis.

The Telegrafia buildings were procured by Eduard Štejnar and Emil Štejnar from České Budějovice. The brothers manufactured furniture fittings. They extended the plant and relocated all their production capacities to Velešín in 1928. Later, the company was renamed “Bratři Štejnarové – továrna na kovové zboží ve Velešíně” (Štejnar Brothers - Metal Goods Manufacturing in Velešín”).

During the Great Depression, the company was forced to dismiss most of the employees but remained viable. The breakthrough came when Antonín Železný joined the company in 1933. This aerospace expert, who married the daughter of Eduard Štejnar, agreed to help upgrade the facility.

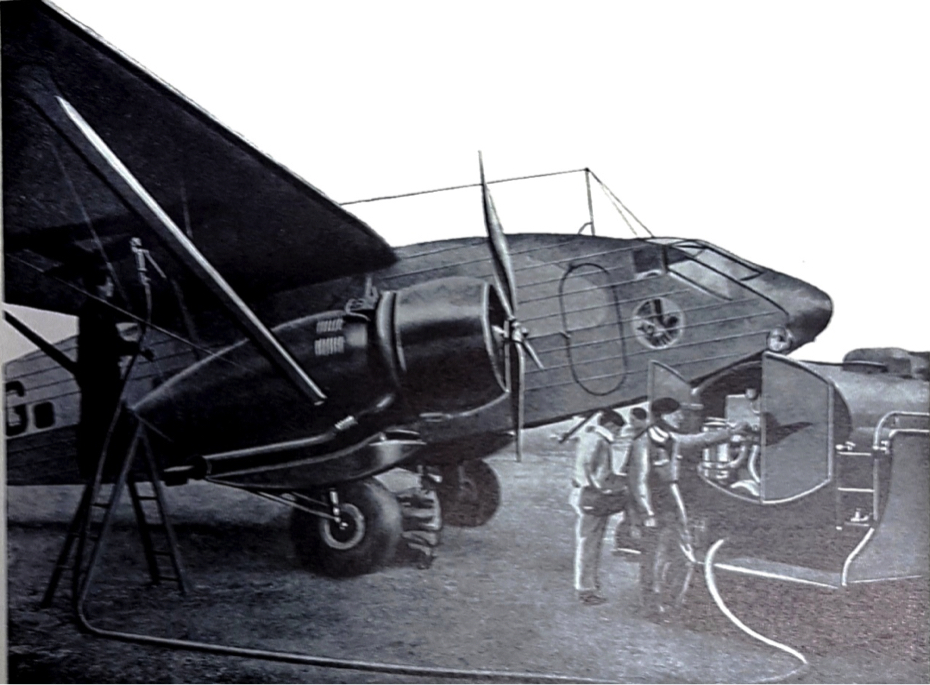

Antonín Železný implemented a rational work organization. He extended the production portfolio with more complex products, such as carburettors. One part of the plant operated under the new name “Pomocný letecký průmysl, Ing. Antonín Železný” (Auxiliary Aircraft Industry, Ing. Antonín Železný). Manufacturing of fuel valves, fuel taps and hydraulic aircraft devices became an important part of the production portfolio in this part of the plant. The other part continued to manufacture metal goods. Both groups merged into the Jikov company in 1938. The company that was controlled by Antonín Železný extended its product portfolio with household appliances.

Following the occupation of Bohemia and Moravia by Nazi Germany, the Jikov enterprise was under forced control of the German armed forces. The plant was required to manufacture parts and devices for the German air force. The number of employees rose to 1500. The owner and his work colleagues joined the resistance movement, assisting families of political prisoners and escaped Russian captives.

After the liberation, all enterprises with over 500 employees were nationalized in Czechoslovakia. Jikov was one of them. Nationalization was followed by a period of organizational changes when the plant in Velešín became part of the Motor Union Group and later of the Motorlet Group, manufacturer of aircraft engines based in Prague.

The controlling bodies assigned an extensive aerospace programme to the Velešín plant within their central planning at the beginning of the 1950s. In particular, the programme covered devices and parts of the engine used for MiG-15 air-fighters. The portfolio of aerospace products grew rapidly. The most important products included devices for the transport aircraft Avia Av-14, the licensed version of Soviet Iljušin II-14.

In 1953, the Velešín plant was removed from the Motorlet Group and established as the national corporation Jihočeské strojírny, Jihostroj in short. Later, Jihostroj was merged with Sdružení československých leteckých podniků Aero (Aero - Syndicate of Czechoslovakian Aerospace Enterprises) based in Prague. This organization did not change significantly until 1990.

It became evident in the 1950s that the company operation could not be sustainable with production focused solely on the aircraft industry since this industry was exposed to frequent demand fluctuations. More stable production programmes had to be introduced. The first of such programmes was the manufacture of wide-angle cine projectors for large and outdoor cinemas. In 1958, the company was ordered to manufacture high-speed centrifuges.

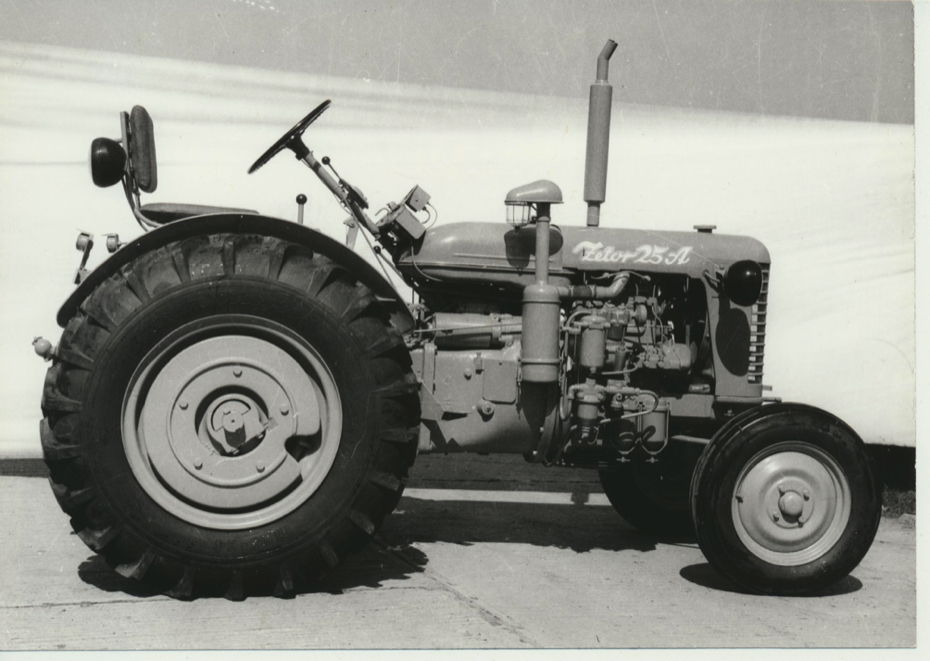

A real breakthrough, however, occurred with the manufacture of gear pumps for power-assisted steering circuits for Tatra trucks and hydraulic systems for Zetor tractors. Since then, manufacturing of hydraulic systems has been the second core business of the company.

The portfolio of hydraulic products continued to grow from the 1950s. It was extended by additional types of pumps for power-assisted steering of motor vehicles, and power hydraulic systems for tractors, forklifts and other machines.

In 1959, a design department focused on the development of aircraft systems and equipment was established in Jihostroj. In 1962, the company started to manufacture products for the training jet plane Aero L-29 Delfin, especially the fuel control system for the M701 engine.

At that time, the plant also manufactured devices for the reduction of dust in underground mines. These devices were manufactured for thirty years. On the other hand, the manufacture of large cine projectors was terminated since more advanced devices were introduced on the market.

The 1970s was a time of Jihostroj’ s development associated with extensive investments. At that time, the company started to manufacture sophisticated aircraft systems that are still in its product portfolio in an upgraded design. For the first time, the company manufactured fuel system for auxiliary power units (APU) for engine start-up. Furthermore, Jihostroj started to produce systems and products for the propeller-turbine engines M601 and aircraft L-410 that used this type of engine. Initially the company manufactured fuel pumps and fuel control units, later also propeller governors.

In the field of hydraulics, the company planned a project concentrating on gear pump manufacture. There was a growing demand for mobile hydraulic units in Czechoslovakia and it was desirable to unify their production. The purpose was to develop a modular system allowing combinations of parts according to customer requirements. Therefore, a project of unified pump series of three dimensions was developed. As a result, Jihostroj became a monopoly manufacturer of gear hydraulic generators in Czechoslovakia after 1976. These products were used for tracks, buses, and forklifts as well as for building, agricultural and other machines.

The growth of production required additional capacity. Therefore, a manufacturing plant in Kaplice was merged with Jihostroj in 1971. Consequently, the company expanded the most in its history. In addition to investment in its own production capacities, Jihostroj initiated house building in Velešín and Kaplice. New blocks of apartment houses were developed in both towns. While the company employed 1,790 people in 1970, there were 3,332 employees working for Jihostroj in 1985.

Foundations of a third plant were laid in Český Krumlov in 1982. During the 1980s, house building continued in Velešín, Kaplice and Český Krumlov, including health centres, day-care centres and leisure amenities. Supported by Jihostroj, the town of Velešín built a cinema and a community centre, while Kaplice developed lodging houses and a rehabilitation centre. The company procured a building in České Budějovice in planning construction of a technological centre and initiated construction of a vocational school in Velešín.

Consequently, the production halls were fitted with modern production technology, such as semi-automatic machine tools for the processing of aerospace materials and the first numerically controlled machines.

The biggest customers of Jihostroj in the hydraulic sector were Tatra Kopřivnice, Liaz Jablonec nad Nisou, Zetor Brno, Desta Děčín, ČKD Slaný, Slovácké strojírny Uherský Brod and Karosa Vysoké Mýto. Aerospace products were sold mainly to Motorlet Praha, Aero Vodochody, Let Kunovice, PBS Velká Bíteš, Moravan Otrokovice and many repair facilities.

This extensive growth, however, was coming to an end in the late 1980s showing its negative impact. This was evident mainly within the group of aerospace manufacturers that was oriented towards the Soviet Union and other Eastern markets.

The economic life of the Eastern Bloc with exception of careful Czechoslovakia suffered high indebtedness. The main foreign buyers of Czechoslovak airplanes had almost no resources to pay. Contrary to expectations, Soviet orders of L-410 airplanes and L-39 military airplanes were cancelled. Moscow explained that by an allegedly exaggerated price. In 1988, the pressure on the reduction of the price for aerospace products resulted in reduced sales of CZK 516 million compared to the planned CZK 578 million. This reflected negatively in the profit.

In 1988, the new State Enterprise Act came into force. According to this Act, enterprises were more responsible for their own economy and should use self-management. The entire Aero Group, of which Jihostroj was a part, was transformed into a state enterprise of concern type. Individual national enterprises, including Jihostroj, became group companies.

Although manufacturers of aircraft and engines lost a clear sales perspective, they continued manufacturing according to the plan, taking the risk that their products would stay in stock unsold. Jihostroj, however, supplied also hydraulic systems and needed to increase its production in this sector.

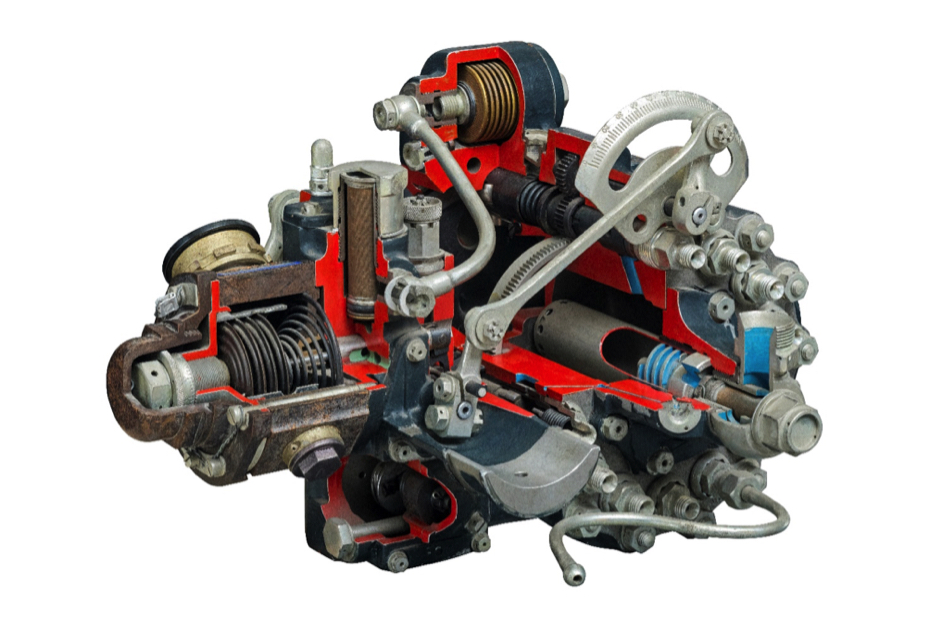

Furthermore, Jihostroj was under strong pressure due to aerospace development projects concerning systems and equipment for the planned L-610 aircraft with M602 engines and devices for DV-2 jet engines. The fuel control unit for the DV-2 engine is probably the most complex product that Jihostroj has ever developed. This engine drives the L-59 training aircraft exported under product name Super Albatros.

The management of Aero Group hoped that these new products would help to recover from the loss in sales of existing products and enter new markets. With the new generation of military training aircraft, however, they managed to do so only partly. The L-610 airplane did not make it to a series production at all.

Since 1988, uncertainty within the Aero Group, as well as personal conflicts, caused Jihostroj to consider separation. Furthermore, separatism occurred also in the Kaplice plant of Jihostroj. The concern rejected these intentions. On 1 January 1989, the concern decided that Jihostroj remain part of the Aero Group under the new shorter name Jihostroj and the Kaplice plant remain under the control of Jihostroj, while the plant in Český Krumlov was in the position of an operating plant of the Velešín enterprise.

After 17 November 1989 the political situation changed and many new things happened rapidly. Before the end of 1989, the management of Jihostroj decided to apply for establishment of a separate state enterprise under the new conditions. This was completed in 1990.

The independent Jihostroj had to face an unfavourable business situation. Most of their long-term customers experienced existential crisis due to the situation on the eastern markets. Some customers, such as Motorlet, ordered goods but failed to pay. As a result of that Jihostroj reported a book profit and was required to pay tax, but did not receive any money. The company experienced its worst existential crisis since 1925.

Within the revolutionary events Jihostroj discussed a change in its name and logo. There was a suggestion for the name "Aero Technology & Hydraulic". In the end, however, these words just complement the logo and the company has kept its traditional name.

It was clear that the existing customers were not enough for Jihostroj to survive. The main priority was to find new business partners. Initially, the company had no experience in doing business on western markets and therefore had to arrange for many training courses and retraining schemes.

The state enterprise Jihostroj was to be transformed into a joint-stock company and privatized. The joint-stock company Jihostroj a.s. was incorporated in the Trade Register on 1 May 1992. This company then went through voucher privatization. Citizens of Czechoslovakia, alone or through privatization funds, were able to order its shares.

The method of voucher privatization allowed rapid privatization of state enterprises; however, it failed to bring capital to enterprises and resulted in fragmented ownership. The company had over six thousand owners at the completion of the voucher privatization. The owners were individuals as well as funds that tried to buy shares from minor shareholders.

The economic situation of the joint-stock company declined significantly during the privatization process. Sales fell sharply, and losses kept growing. There was a high fluctuation of the management.

The investment company Rentia Brno attempted to redevelop the company. Representatives of this investment fund, however, had no practical experience necessary for the management of a large industrial enterprise. It became clear that the company could not survive without an experienced person in the position of CEO.

Eduard Železný, son of the pre-war CEO, started to visit Jihostroj shortly after privatization. He was unable to apply for restitution, since companies nationalized before 1948 were not eligible for restitution and subjected to the voucher privatization. He concluded that only a competent manager could save the company and started to look for one.

It was not an easy task since the condition of the company seemed to be helpless. None of the originally considered candidates were prepared to move from Prague for a totally uncertain position. Later, Eduard Železný received a tip for a manager and technician from the South Bohemian company ČZ Strakonice. He suggested that this man become the new CEO. Jiří Gerle joined the company in the middle of 1994.

The company stabilized gradually under management of the new CEO. After recovering from the worst condition, Jihostroj took advantage of its extensive real estates procured before 1990. Selling buildings no longer needed saved the company from bankruptcy.

Based on analysis, the new CEO concluded that Jihostroj should not seek a fundamentally new production programme and continue developing aerospace systems and hydraulic products instead.

However, the demand of the domestic manufacturers of new aircraft dropped. Therefore, in the 1990s the main production of Jihostroj in the aerospace sector included spare parts for overhauls of devices for the high number of L-410 aircraft that were originally operated on domestic flights in the former Soviet Union and from there they were procured by other owners all around the world. The unused capacity of the aerospace section of Jihostroj was utilized for the manufacture of surgical instruments, such an orthopaedic air drillers, surgical saws and vibratory saws for plaster bandages.

Also, production of hydraulic products dropped rapidly at the beginning of the 1990s. In 1989, Jihostroj manufactured 263,000 hydraulic pumps and motors; in the next year this number fell to less than one third. This was mainly due to the situation of Czech and Slovak customers. Gradually, Jihostroj managed to find new customers in the West for its hydraulic pumps. Among the first were the Italian companies Hydrocar and OMFB.

Initially, the company accepted to work in hired labour mode for western customers. Jiří Gerle, CEO and later owner of the company, however understood such cooperation to be a bridge to overcome the crisis. The company maintained its own development department and testing facilities. Sophisticated aerospace systems and hydraulic products offered by Jihostroj to customers are again a result of the company’s own development.

The economic situation of the company improved rapidly, associated with growing investments, export and work productivity. The company, however, lived with the production split into three different locations as heritage from the past times. In 1997, the plant in Český Krumlov was procured by the German company Linde, manufacturer of forklifts. The plant in Kaplice was procured by the Austrian company Engel for the manufacture of injection moulding machines. In 2001, Jihostroj moved all its operations to the plant in Velešín. This was a complicated project considering the large number of machines that had to be relocated. The project, however, resulted in rationalization of production and cost reduction.

Jihostroj managed to start cooperation with the aerospace division of the American corporation Parker Hannifin based in Irvine, California, USA. In addition to Parker, Jihostroj gradually attracted other important customers, for example Honeywell, Crane Aerospace, Safran Group, Samsung Techwin and others.

Furthermore, the situation of many traditional customers of Jihostroj’s aerospace division improved. GE Aviation Czech continues to manufacture propeller-turbine engines in Prague. Other domestic customers include PBS Velká Bíteš, Aero Vodochody Aerospace and former Let Kunovice, today Aircraft Industries.

In the hydraulics sector the company started a business relationship with Sachsenhydraulik from Chemnitz, Eastern Germany, which was procured by the American Commercial Intertech in 1994. This merger resulted in the rapid development of cooperation. In 2000 this American company has been procured by the hydraulics division of Parker Hannifin. By coincidence, both strategic business partners of Jihostroj have been merged into one, currently the biggest customer.

Business with Parker Hannifin has been a top-class reference. More customers kept coming to us. As a result of that, Jihostroj has transformed into an export enterprise with the biggest market in USA. The company has additional big foreign customers in Germany, France, Italy, Israel, South Korea and Russia.

Jihostroj’ s products are used in many different application from airplanes to vehicles of all kind, through construction, agricultural, handling and communal service machines, to wind power plants.

The company has reconstructed its entire 15 ha site. This process has taken several years. Buildings have been restored and thermally insulated, production facilities have been moved to fewer buildings, a number of old buildings have been demolished, roads have been completed and decentralized heating has been installed. That has resulted in significant cost savings.

Jihostroj enters the hundredth year of its existence as a stable company operating advanced technology. It is focused on innovations, high technical standards and top quality of its products.

Currently, the manufacturing programme of Jihostroj’s aerospace division consists of four parts: In addition to engine fuel control systems the company manufactures fuel control systems for auxiliary power units, propeller governors and airframe hydraulic and fuel systems.

The biggest customer of engine fuel control systems is GE Aviation. Jihostroj delivers fuel control systems for auxiliary power units to helicopter manufacturers, such as Korea Aerospace Industries that assembles Surion helicopters, and Italian manufacturer Leonardo for their AW189 helicopter. Jihostroj offers its propeller governors to its customers in many alternatives. About six thousand speed governors are used by pilots in the USA.

The hydraulics division of the company manufactures about 250,000 gear pumps and hydraulic motors annually. Jihostroj’s portfolio of these products is very broad and includes about 20,000 options usually tailored to the needs of individual customers.

Furthermore, Jihostroj is considering the establishment of an assembly plant in Russia.

The company, however, is not only active in manufacturing. It has a close cooperation with secondary schools and universities, acts as a good citizen of its town, supporting communities and sport clubs.

During its existence, the company has managed to overcome hard times, fundamental political changes as well as deep economic depressions.

The experience, expertise and craft of Jihostroj’s employees provide a guarantee for the continuous development of advanced engineering in Velešín.